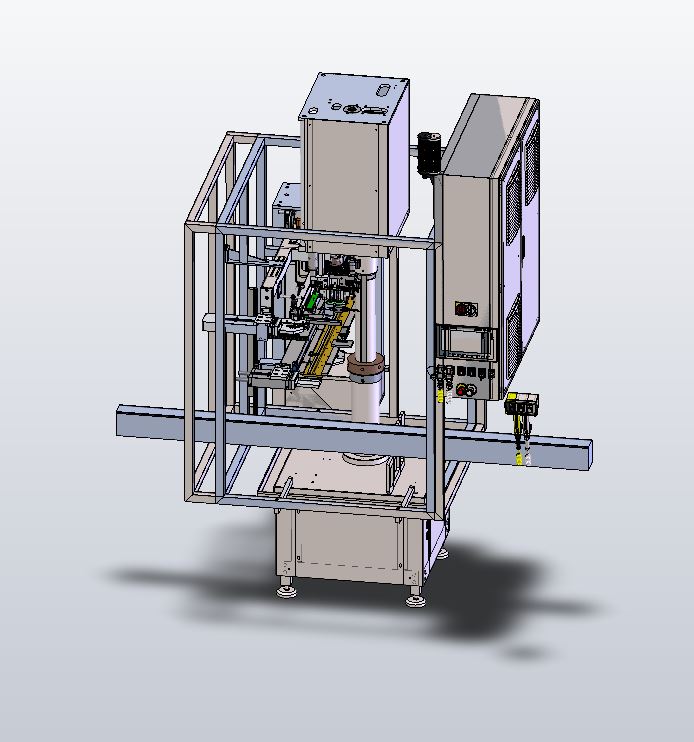

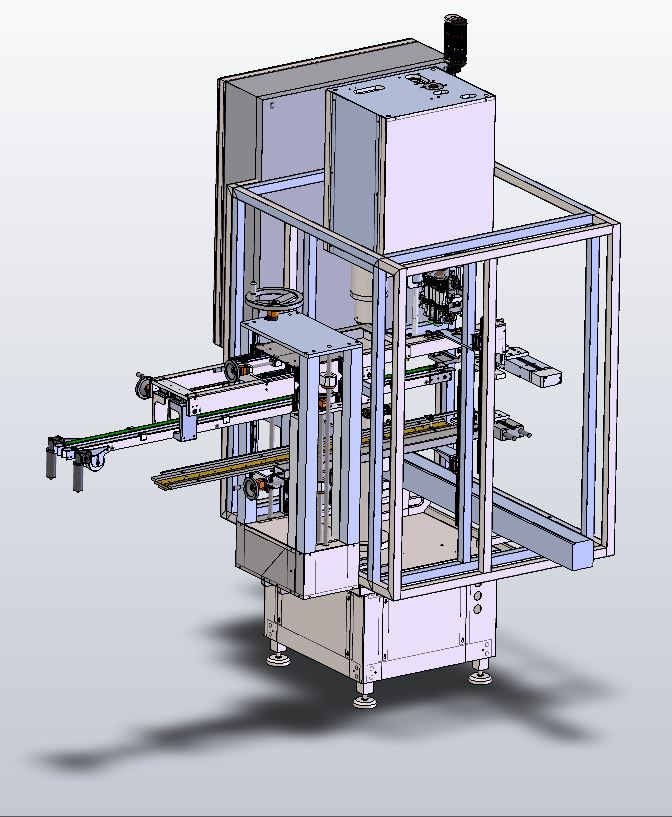

Screw cap closing machine VER001L

full automatic inline Capping machine type VER 001-L, to seal bottles and containers. The bottles run on the conveyor into the machine. The bottles become separated through different speed of the conveyorbelt and the side belts wich are guiding the cans through the machine. The sealing head catch the cap from the cap station and bolt the cap together with the bottle without stopping the canister also without splashing. The equipment includes a 3m long conveyor with frequency controlled drive. All windows and doors are designed with safety switches. The electric control consists PLC of Siemens SPS S7. Pneumatic components are from Festo.

The machine is delivered with one format set for bottles and caps.

| Performance | about 2700 bottles per hour, smoothly adjustable, depending on the form of the trading units and screw cap dimensions |

| Cap feed | from sorter to closing unit via cap plate with brass feeding rail and stainless steel |

| Machine drive | frequency drive |

| Transport |

|

| Screwing head drive | servo drive, Torque adjustment via PLC .. |

| Machine management | Siemens SPS S7, control touch panel |

| Festo pneumatic | valves and cams |

| valves and cams | in solid steel-aluminum-construction, lacquered table sheets and side casing in stainless steel |

| Control device |

|

| Safety device |

|

| Working height | 900 mm +/- 50 mm |