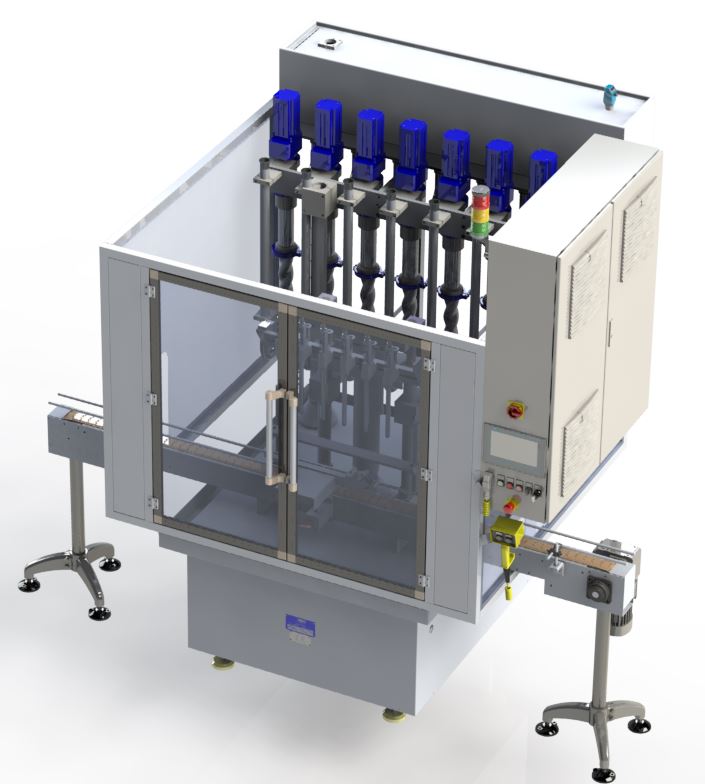

Mohno pump filler

Fully automatic linear filling machine with singularization or stop star for product singularization. The machine is completely equipped by mono pumps in the CIP convenient execution (e.g. for the food sector). The equipment contains a frequency commanded conveyor drive. The machine can be fitted for service with cups or for normal product filling. Other formats can be programmed via the machine management.

All pumps, valves and cylinders are made of stainless steel. Die residual depletion is made directly by the piston. The seals are made of Viton or Variseal.

The machine is delivered with bottle format, optionally in the CIP-SIP execution.

| Performance | up to 6,000 (FDK 1800) bottles per hour, smoothly adjustable, depending on the form of the trading units, filling height and product |

| Transport | one track plastic slat conveyor chain with smoothly adjustable drive and guide railing |

| Machine drive | frequency drive |

| Pump drive | stepping motor adjustable and controllable in all velocities and proceeding ways, rpm and rotation free programmable via machine control panel. The pumps have to be fed constantly with the product. Dry running of the pumps can be avoided by means of a reservoir with float command. |

| Machine management | Siemens SPS S7, control touch panel OP177B Optionally, also with servo drive |

| Festo pneumatic | valves and cams |

| Basic frame | in solid cast-steel-aluminum-construction, lacquered, table sheets and side casing in stainless steel with collecting vat |

| Control device |

|

| Safety device |

|

| Working height | 900 mm +/- 50 mm |